Industries We Support with Mission-Critical Equipment

TRW Industries delivers engineered solutions across demanding industrial environments where uptime, safety, and performance matter most.

Wind Energy

Specialized tools supporting safe stud removal and installation during turbine maintenance.

Learn More

Oil & Gas

Field-proven tooling designed for stud removal in high-pressure, hazardous environments.

Learn More

Marine & Offshore

Corrosion-resistant tools engineered for offshore and marine maintenance operations.

Learn More

Power Generation

Precision tools supporting fast, controlled maintenance on critical power assets.

Learn More

Mining & Heavy Equipment

Heavy-duty tools built for large-scale equipment repair and extreme service conditions.

Learn More

Petrochemical / Refinery

Controlled stud removal solutions designed to improve safety during shutdowns.

Learn More

Aerospace

Precision-manufactured tools supporting strict aerospace maintenance requirements.

Learn More

Rotating Equipment

Tools designed for controlled stud removal on compressors, turbines, and pumps.

Learn More

Manufacturing & Industrial Maintenance

Reliable maintenance tooling designed to minimize downtime and labor risk.

Learn More

Transportation & Rail

Durable tools engineered for maintenance on high-load transportation equipment.

Learn More

Military & Defense

Precision tools supporting safe, controlled maintenance on mission-critical defense equipment.

Learn More

Heat Exchangers

Specialized tools designed for controlled stud removal during heat exchanger maintenance.

Learn More

Distributor/Reseller Program

Product Catalog

TRW Industries

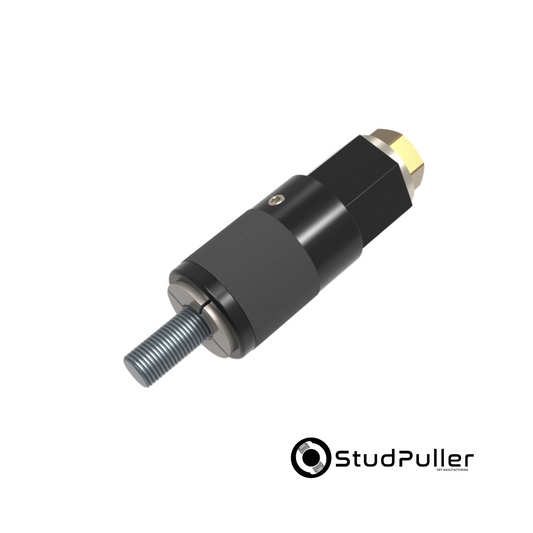

StudPuller

Select a Method:

Safety:

Safer; Reduces Risk of Injury

Operator injury could occur when over tightening or shearing a stud.

Possible burn or ignition of other materials

Flying debris & metal shavings

Back injuries

Science:

The StudPuller uses two opposing jaws on internal cams to grip and squeeze studs to

create rotation of the stud.

Binding two nuts against each other creates a mechanical bind, which stretches the threads

Damages stud and possibly the housing

Drilling a stud is a slow, heat-building process that grinds away metal with risk of slipping off-center and damaging threads.

Side loading occurs when “pulling” on a stud. This creates a mechanical bind in the threads

Common Issues:

Rotation is the fastest, safest and least expensive way to remove studs. issues are lack of training, burning jaws, under powered equipment, lack of proper air supply.

Nuts just rotate and don’t lock against each other, nuts won’t release after extraction, stretches threads, uses lots of time

Having a welder on hand, nut doesn’t weld on center, weld breaks, stud destroyed

Inordinate amount of time, getting drill into tight spaces, set up time just to get started, possible damage to housings

Safety issues: pulling on a breaker bar is extremely dangerous and bad for the back, heavy side loading, damaging the housings and threads, bending studs or shearing studs

Productivity:

Fastest; Increases Productivity

Slow

Slow time to weld and cool

Slow time spent doing set up and drilling

Very slow

Materials Used:

StudPuller

2 Nuts

1 Nut

Machine tools or drill press

Pipe wrench and breaker bar

Need to find the perfect tool?

Try our Quiz